Kellogg's Robot Cell Upgrade Reduces Cycle Time 67%

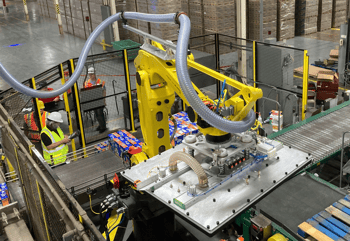

Building a new robot palletizing station reduced cycle time by 67%, allowing food & beverage industry giant Kellogg’s to meet aggressive new throughput goals.

Fill out the form below to download the Kellogg's Robot Cell Upgrade case study.Throughput is a major concern in the manufacturing world and is often hindered by bottlenecks created by outdated equipment. For one Kellogg Company facility, the twelve-year-old palletizing robot station was unable to keep up with growing customer demands.

CHALLENGE

The Kellogg’s manufacturing facility in Memphis, Tennessee was looking to expand the production of bulk size cereal boxes for a wholesale club retailer client. The business plan called for increasing the annual production volume by about 8.3 million pounds of cereal, a 43% increase in the number of pallets coming through the system each day. Kellogg’s wanted to meet this demand without adding additional manufacturing lines. With this large growth on the horizon, Kellogg’s looked at process improvements to meet their goals.

SOLUTION

The new system was comprised of the following items:

- Robot pedestal

- FANUC M-410iC/185 palletizing robot, controller, and dress pack

- 16-horse power blower unit sized for new Piab EOAT

- Layer picking Piab EOAT

- Allen Bradley ControlLogix L8 PLC

- Ethernet card

- Field Ethernet devices

Fill out the form below to download the Kellogg's Robot Cell Upgrade case study.